What Is the Role of Fumed Silica In Rubber?

HIFULL® Fumed Silica: The Unsung Hero Behind Rubber’s Evolution

Fumed silica, as an advanced ultra-fine inorganic nanomaterial, demonstrates remarkable application advantages in rubber products and tire industries due to its unique physical and chemical properties. Through years of practical exploration and innovative experimentation, technical experts at HUBEI HUIFU NANOMATERIAL CO., LTD. have conducted in-depth research on the roles, functions, and applications of fumed silica in rubber and silicone rubber fields, along with its dosage effects on product performance enhancement.

HIFULL® fumed silica is a nanometer amorphous silica obtained by high-temperature hydrolysis of halosilane in oxyhydrogen flame. It is characterized by high purity and a narrow particle size distribution, with primary particle sizes typically ranging from 7 to 40 nm and specific surface areas varying between 90 m2/g and 450 m2/g. After surface modification, fumed silica comes in a wider variety of types and offers more comprehensive functions.

These characteristics endow it with superior performance in reinforcing, thickening, thixotropic, anti-sagging, anti-settling, matting, and insulating properties.

application In fluorosilicone rubber

In fluorosilicone rubber applications, fumed silica can be used as a reinforcing filler to significantly enhance the mechanical strength of the rubber. Its high specific surface area and nanometer particle size enable it to form strong bonds with fluorosilicone rubber molecules, creating a three-dimensional network structure that effectively limits the deformation of rubber molecular chains.

As a result, the tensile strength, tear strength, and other mechanical properties of fluorosilicone rubber are enhanced. Additionally, due to the inherent high hardness of fumed silica, its combination with fluorosilicone rubber can increase the surface hardness of the rubber, thereby improving its wear resistance.

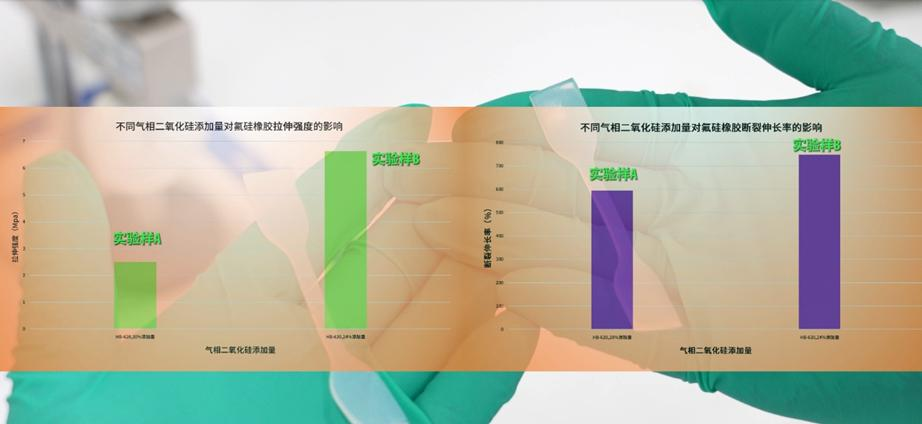

Experimental results showed that the addition of 20% and 24% hydrophobic fumed silica HB-620 into fluorosilicone rubber significantly enhanced both the tensile strength and tear resistance of the vulcanized dumbbell-shaped sheets after compression molding.

HIFULL® HB-620 (BET=200㎡/g)

Specifically, at a 24% loading, the fluorosilicone rubber exhibited a 160% increase in tensile strength and a 25% improvement in elongation at break compared to the 20% loading.

application In silicone rubber

In silicone rubber applications, the relatively soft molecular chains of silicone rubber result in limited mechanical properties. Due to its nanometer particle size and high specific surface area, fumed silica can form a three-dimensional network structure with silicone rubber molecular chains through physical adsorption and chemical bonding, acting as “bridges” and “anchors.”

This significantly enhances the mechanical properties of silicone rubber, including tensile strength, tear strength, and hardness. Additionally, it improves weather resistance, flame retardancy, and thermal stability.

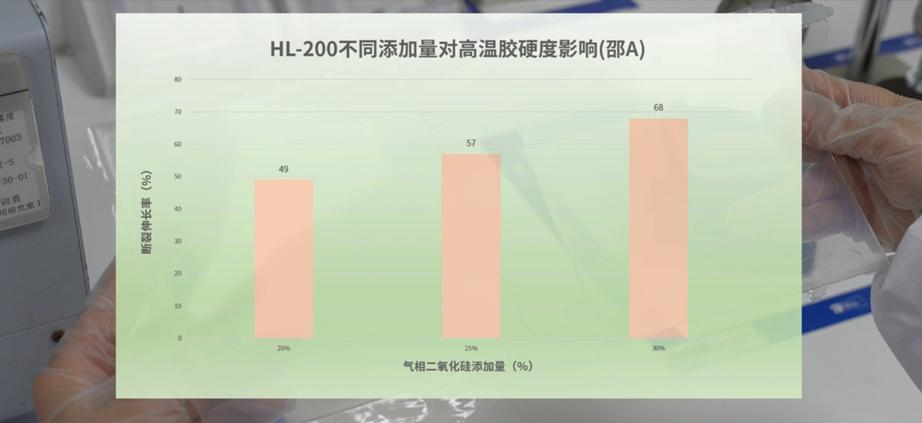

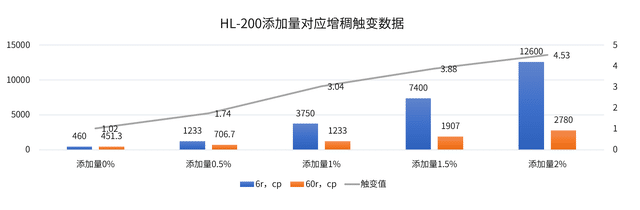

Experimental results showed that the addition of 20%, 25% and 30% hydrophilic fumed silica HL-200 into HTV silicone rubber significantly enhanced the mechanical properties of the prepared specimens. Universal material testing machine measurements revealed that the 25% loading formulation showed a 66% improvement in tensile strength compared to the 20% loading, while the 30% loading formulation exhibited a further 25% increase over the 25% loading. However, the incremental enhancement diminished with increasing filler content.

In hardness testing, the hardness values of HTV silicone rubber with 20%, 25%, and 30% hydrophilic fumed silica added were 49, 57, and 68, respectively. The 25% loading formulation demonstrated a 16% increase in hardness compared to the 20% sample, while 30% loading formulation showed a further 19% improvement over the 25% formulation, demonstrating growing enhancement with higher loading levels.

Evidently, fumed silica demonstrates remarkable advantages in rubber and silicone rubber applications, significantly enhancing mechanical properties, wear resistance, processing performance, and thermal stability, providing substantial support for various industrial applications.

Silicone Rubber

However, practical application studies reveal that key considerations must be addressed, including optimal loading control, dispersion improvement, and the application of surface-modified products. Only through such comprehensive optimization can rubber products achieve their optimal performance in emerging sectors like new energy vehicles, mechanical equipment, petrochemical engineering, and aerospace applications.