Performance Comparison: HIFULL VS. International Fumed Silica in Battery Adhesives

With the booming development of the new energy vehicle industry, the automotive sector has entered an era of performance arms race. The competition over power battery safety and stability is intensifying. As a critical material in battery assembly, the performance of adhesives directly impacts overall battery quality.

Gradually, an often-overlooked “invisible material” is quietly entering the arena, influencing power battery safety and reliability through its unique characteristics and properties.

As a commonly used functional additive and reinforcing agent for adhesives, fumed silica plays a crucial role in enhancing the performance of power battery adhesives. However, the market offers numerous brands of fumed silica with varying quality, leading to differences in their impact on adhesive properties.

To further investigate the variations between HIFULL® fumed silica and domestic/foreign competitors in power battery adhesives, a comparative analysis was conducted on key performance indicators including tensile strength, elongation at break, shear strength, anti-sagging properties, and thermal storage stability.

Battery

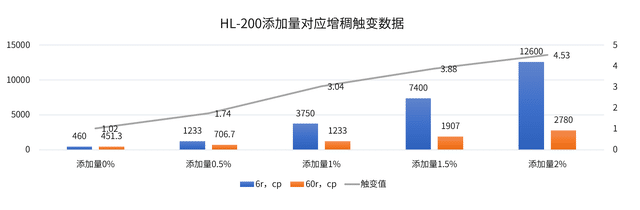

This study focused on six fumed silica products: HB-139, HB-139B, HL-200, Foreign Competitor A/B, and a Domestic Competitor, with a blank control group included for reference.

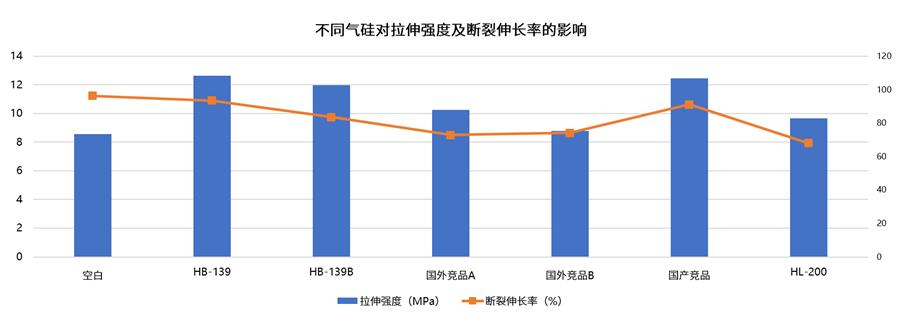

In the tensile strength and elongation at break experiments, technical personnel at Hubei Huifu Nanomaterial Co., Ltd. used a 3% additive ratio with polyurethane power battery adhesive as the test material. The substrate was molded into dumbbell-shaped specimens, cured at 50°C for 14 hours, and then tested for tensile strength and elongation at break using a universal material testing machine.

The data shows that both hydrophilic and hydrophobic fumed silica can improve the adhesive’s tensile strength, while simultaneously reducing its elongation at break. In tensile strength comparison, HB-139 and the domestic competitor showed similar improvement values. Test results indicate the blank sample had a tensile strength of 8.56 MPa, while HB-139 achieved 12.62 MPa – a 47% increase in tensile strength. Regarding elongation at break, the blank sample measured 96.26%, whereas HB-139 showed 93.48%, representing only a 2.78 percentage point reduction, the smallest decrease among all tested brands.

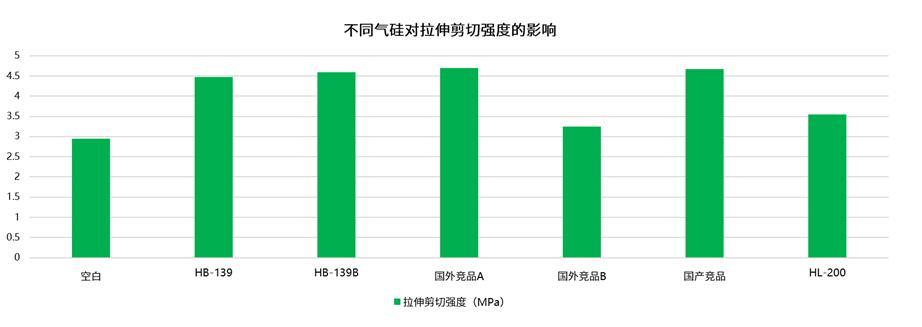

In the lap shear strength experiment, technical personnel at Hubei Huifu Nanomaterial Co., Ltd. used a 3% additive ratio with polyurethane power battery adhesive as the test material, bonding aluminum alloy substrates. After curing at 50°C for 14 hours, samples were tested using an electronic universal testing machine.

Test data indicates both hydrophilic and hydrophobic fumed silica can improve the adhesive’s lap shear strength. HB-139/139B demonstrated comparable performance to Foreign Competitor A and the domestic competitor. The blank sample showed 2.95 MPa lap shear strength, while HB-139B achieved 4.59 MPa, a 55% improvement.

| type | Component A | Component B |

|---|---|---|

| Drop length (10 min, mm) | Drop length (10 min, mm) | |

| / | 50 | 50 |

| HB-139 | 0 | 0 |

| HB-139B | 1 | 1 |

| International Brand A | 1 | 0 |

| International Brand B | 2 | 0 |

| Chinese Brand A | 2 | 0 |

| HL-200 | 12 | 50 |

For anti-sag testing, both Component A and B of the polyurethane adhesive were evaluated. Results confirm fumed silica significantly enhances anti-sag properties. Without fumed silica, both components showed 50mm sag length within 10 minutes. With hydrophilic HL-200 added, Component A’s sag reduced to 12mm while Component B remained unchanged. Among hydrophobic types, HB-139 in Component A achieved 0mm sag, the best performance, while HB-139 in Component B showed similar results to foreign and domestic competitors.

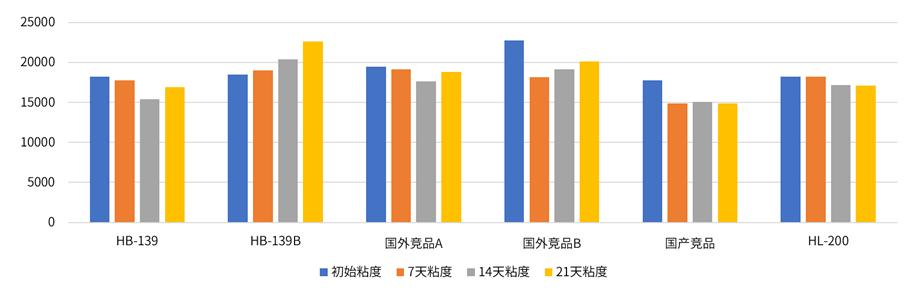

In thermal storage testing with 3% fumed silica in Component A, viscosity was measured initially and after 7, 14, and 21 days at 50°C. HB-139B demonstrated increasing viscosity over time, while other fumed silica products showed decreasing viscosity trends during storage.

Comprehensive analysis reveals significant performance variations among different fumed silica brands. HB-139 excels in tensile strength, elongation at break, and anti-sag properties, making it ideal for applications prioritizing these characteristics. Both foreign and domestic competitors also demonstrate competitive performance across multiple indicators.

When selecting fumed silica products, battery manufacturers should consider their specific adhesive performance priorities. Products with excellent tensile strength and elongation are preferred for vibration resistance and deformation prevention, while superior anti-sag types benefit production process requirements. As power battery technology advances, continuous improvement in fumed silica formulations remains essential to meet evolving adhesive performance demands.