In aerospace, automotive, and electronics industries, high-temperature vulcanized (HTV) silicone rubber serves as a critical sealing and bonding material, routinely exposed to extreme temperatures exceeding 200°C. However, conventional high-temperature adhesives often suffer from molecular chain degradation and reduced crosslink density under prolonged thermal stress, leading to a sharp decline in mechanical properties such as tensile strength and elongation at break, severely compromising service reliability.

The emergence of fumed nanomaterials offers a promising solution to this bottleneck: leveraging the nanoscale effect and high specific surface area of nanoparticles to establish unique interfacial interactions with the polymer matrix, thereby effectively mitigating thermal aging.

Among these, fumed titanium dioxide (TiO₂) stands out as an ideal reinforcing candidate for high-temperature adhesives due to its exceptional thermal stability, chemical inertness, and reinforcement potential. Researchers at HUBEI HUIFU NANOMATERIAL CO., LTD. conducted a controlled study under harsh conditions, continuous aging at 275°C for 24 hours, to compare the evolution of tensile strength and elongation at break between a blank sample and a formulation containing 1.5% nano-TiO₂, thereby revealing the stabilizing role of fumed titanium dioxide in high-temperature adhesives.

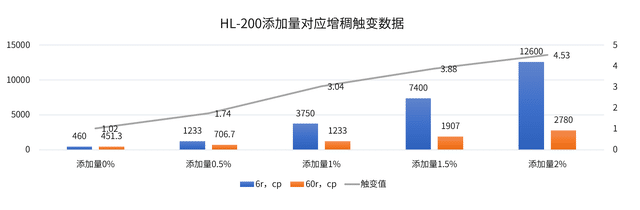

Figure 1

Tensile strength data were systematically recorded (Figure 1). Initially (0–2 h), both samples exhibited comparable tensile strengths of approximately 7 MPa. However, after 2 hours of thermal aging, the blank sample’s strength dropped rapidly, plummeting to just about 1 MPa by the 24-hour mark. In stark contrast, the fumed titanium dioxide -enhanced adhesive showed a markedly slower degradation trend, retaining a robust tensile strength of about 6 MPa even after 24 hours at 275°C.

This performance gap arises from two key mechanisms.

First, the nanoscale size of TiO₂ enables strong interfacial bonding with the polymer chains, under tensile stress, load is efficiently transferred from the matrix to the nanoparticles, preventing stress concentration within the bulk material.

Second, the chemical stability of TiO₂ suppresses oxidative degradation at elevated temperatures, slowing the loss of crosslinks and chain scission, thus preserving a relatively intact network structure over extended thermal exposure.

Conversely, the blank sample, lacking such protective mechanisms, undergoes progressive chain breakage and crosslink loss, resulting in catastrophic mechanical failure.

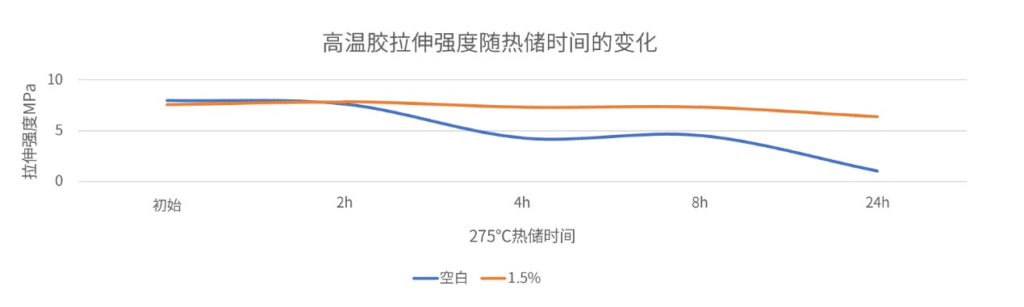

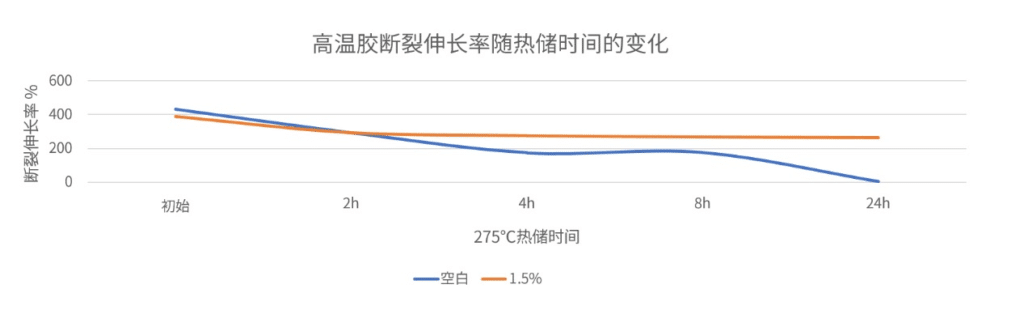

Figure 2

Figure 2 illustrates the evolution of elongation at break under the same aging conditions. Initially, the blank sample displayed a slightly higher elongation (about 420%) compared to the fumed titanium formulation. However, divergence became evident after just 2 hours: the blank sample’s elongation continuously declined, approaching 0% by 24 hours, indicating near-complete loss of ductility due to severe molecular degradation. Meanwhile, the fumed titanium-enhanced adhesive maintained stable elongation throughout the test, retaining about 250% even after 24 hours at 275°C.

This resilience stems from the uniform dispersion of fumed titanium particles within the rubber matrix, which act as nanoscale physical crosslink points. These restrict random thermal motion of polymer chains, reducing thermally induced scission, while also distributing applied stress more evenly to prevent localized strain concentration and brittle fracture. The dramatic contrast between the collapsing performance of the blank sample and the sustained ductility of the nano-reinforced adhesive underscores the significant role of fumed titanium dioxide in enhancing thermal dimensional stability.

Although base polymers like silicone rubber and fluororubber inherently possess good high-temperature resistance, their pure forms still suffer from performance decay under extreme conditions, a persistent industry challenge. The incorporation of fumed titanium (e.g., grades NT-50/NF-50) offers a novel pathway forward.

This advanced nanomaterial features a mixed-phase structure (anatase and rutile) with a high specific surface area (about 50 m²/g) and abundant surface activity, enabling hydrogen bonding or covalent interactions with the polymer matrix to strengthen interfacial adhesion. Additionally, the steric hindrance effect of nanoparticles restricts polymer chain mobility, further delaying thermo-oxidative degradation.

From an application standpoint, fumed titanium-enhanced high-temperature adhesives not only maintain mechanical integrity after prolonged exposure to 275°C but also open doors to more demanding scenarios, such as aerospace engine seals and automotive exhaust manifold bonding, thereby enhancing the reliability of high-end equipment. Looking ahead, advances in nanocomposite technologies (e.g., multidimensional nanoparticle synergies, surface grafting modifications) will further deepen the performance synergy between fumed titanium and high-temperature adhesives, driving sealing and bonding materials toward higher service temperatures and longer lifespans. This innovation promises to serve as a powerful new engine for technological advancement in strategic industrial sectors.

Hubei Huifu Nanomaterial Co., Ltd(HIFULL). is a chemical manufacturer of nanomaterials in China. Our main products are fumed silica, fumed titanium dioxide and fumed alumina Al2O3. We get 20+ years of expertise and 12,000 tons annual capacity. We are the National Innovative Incubation Base of Fumed Silica & vice president unit of China Association of Fluorine and Silicon Industry (CAFSI). Guangzhou Huifu Research Institute Co., Ltd. is our wholly-owned subsidiary.