Why Fumed Silica Can Be Used In Tile Grout? Principle, Function and Research

Fumed silica, AKA white carbon black, with its unique physical and chemical properties, has demonstrated extensive application value and market demand in the tile grout industry. It has gradually become a critical additive for enhancing grout performance, bringing new development opportunities to the field.

Functions and Mechanisms of HIFULL® Fumed Silica in Tile Grout

Fumed silica, with its ultra-fine particle size, high specific surface area, high surface activity, and powerful adsorption capacity, performs multiple functions in tile grout. The silanol groups (Si-OH) on its surface form a three-dimensional network structure within the resin matrix, which helps increase the overall viscosity of the grout.

This structure is reversible, when subjected to shear force, the viscosity decreases, and when the shear force disappears, the viscosity recovers, preventing the grout from flowing out of joints and ensuring precise application and aesthetic results. Therefore, adding an appropriate amount of fumed silica to tile grout can effectively adjust its rheological properties, making the grout easier to control during application, reducing sagging and dripping, and improving construction efficiency.

Caulking Compound

Secondly, fumed silica can serve as a reinforcing filler that uniformly disperses within the tile grout matrix to provide physical reinforcement. On one hand, the nanoparticles can fill the spaces between polymer molecular chains, restricting their relative movement and thereby increasing material strength.

On the other hand, fumed silica forms interfacial bonds with the polymers in the grout. When external forces are applied, stress can transfer through these interfaces to the nanoparticles, inducing plastic deformation of the surrounding matrix that absorbs energy. This mechanism enhances the grout’s hardness, wear resistance and impact resistance.

Additionally, the nanoscale size of hydrophobic fumed silica enables it to fill microscopic pores in the resin matrix, forming a more compact structure that enhances the grout’s resistance to water, oil, acids, and alkalis.

Experimental Investigation of HIFULL® Fumed Silica in Tile Grout

To further validate the functions and effects of HIFULL® fumed silica in tile grout, technical experts from Hubei Huifu Nanomaterial Co., Ltd. conducted the following experiments:

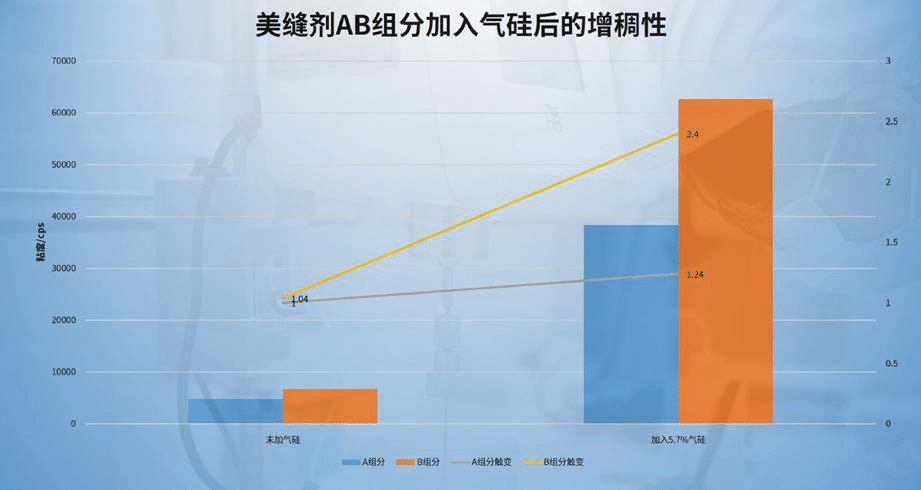

A two-component epoxy resin grout system was selected as the experimental subject, with Component A being epoxy resin and Component B being curing agent. HIFULL® hydrophobic fumed silica was added at 5.7% concentration to both Components A and B respectively, followed by thorough dispersion using a high-speed disperser.

The viscosities and thixotropic values of both the control samples (without fumed silica) and the test samples (with fumed silica) of Components A and B were then measured using a Brookfield viscometer.

The results demonstrated that the incorporation of fumed silica effectively increased the viscosity of the grout components.

Specifically, the viscosity of Component A rose from 4,500 cps to 38,000 cps, approximately 7.4-fold increase, while Component B’s viscosity increased from 5,500 cps to 62,000 cps, approximately 10-fold increase. Regarding thixotropy, Component A showed a 24% improvement and Component B exhibited a 130% enhancement.

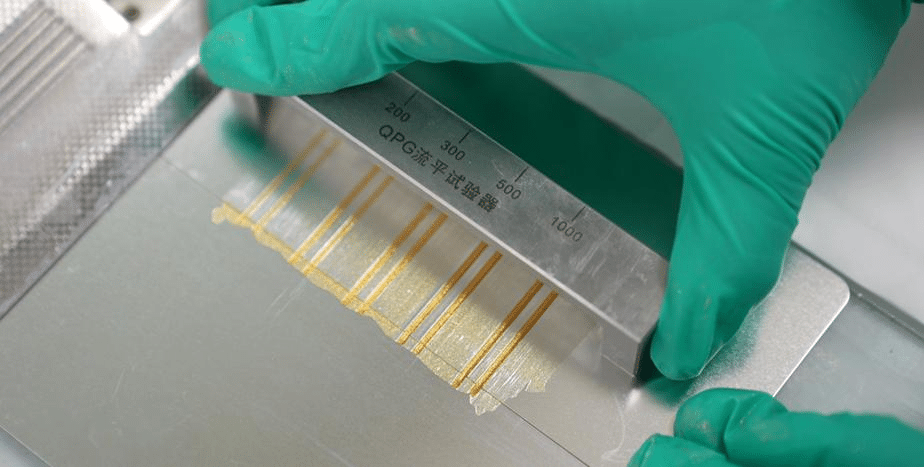

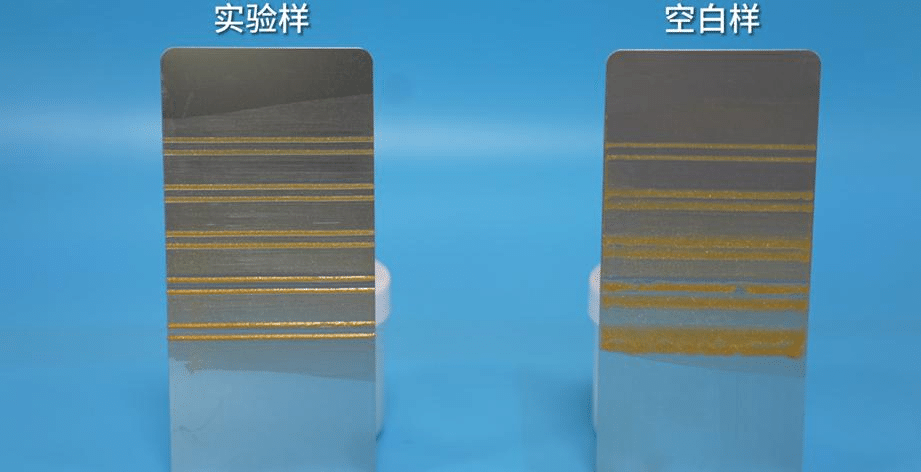

Both the control samples A/B components and the test samples were loaded into packaging tubes and extruded onto a rheological tester using a caulking gun. Samples were then drawn down and applied vertically onto tinplate panels to observe the behavior differences between the control and modified grouts at varying thicknesses.

Technical experts from Hubei Huifu Nanomaterial Co., Ltd. observed that over time, the test sample’s drawn-down strips remained unchanged, while the control sample’s grout on the tinplate panels continuously sagged downward under gravity. The sagging phenomenon became increasingly pronounced with greater application thickness. These results demonstrate that fumed silica effectively enhances the grout’s anti-sagging performance, significantly improving construction efficiency.

anti-sagging performance Test

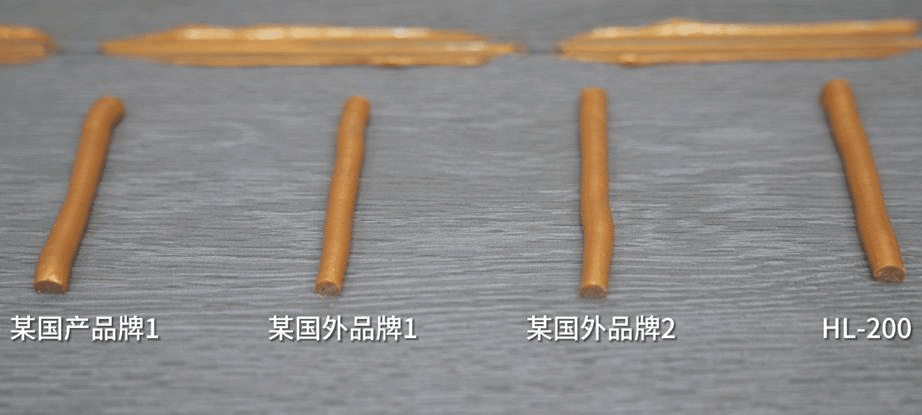

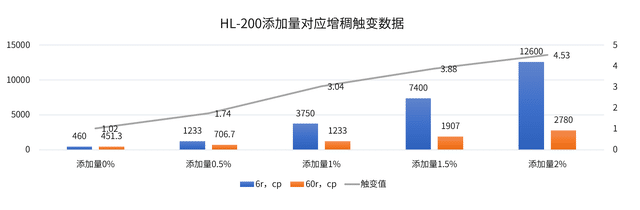

Meanwhile, the technical experts from Hubei Huifu Nanomaterial Co., Ltd. also conducted comparative testing of anti-sagging performance between HIFULL® hydrophilic fumed silica (HL-200) and competing domestic/foreign products.

Fumed Silica Function – Anti Sagging Additive

After adding 6% of each test material (three competitors’ products and HL-200) to Components A/B of the grout respectively, followed by thorough dispersion using a high-speed disperser, similar cylindrical grout strips were extruded using dual-component cartridges.

Extended observation showed none of the grout samples exhibited gravity-induced sagging, with all maintaining their original shapes without deformation.

These results indicate HL-200 demonstrates comparable anti-sagging effectiveness to other hydrophilic competitors in tile grout applications.

conclusion

The above experiments have effectively validated that both hydrophilic and hydrophobic fumed silica can significantly improve the rheological properties, hardness, and mechanical performance of tile grouts. These results confirm the feasibility of using fumed silica as both filler and thixotropic additive in grout products, while providing an effective approach for product upgrading.

However, with continuous market development and increasing consumer demands for performance, further research is still required regarding fumed silica’s mechanisms in grout formulations. Future research priorities for Hubei Huifu Nanomaterial Co., Ltd. will focus on optimizing surface treatment processes and dispersion technologies for fumed silica, as well as developing more innovative and practical grout products. As related research progresses, fumed silica is expected to play an even greater role in the tile grout industry and drive its innovative development.