HIFULL® NT-50 Fumed Titanium Dioxide solves the high-temperature embrittlement problem in silicone rubber

Silicone rubber (including high-temperature vulcanized silicone rubber, room-temperature vulcanized silicone rubber, liquid rubber, etc.) is widely used in electronic packaging, aerospace sealing, automotive manufacturing and other fields due to its excellent properties such as weather resistance, electrical insulation, and resistance to high and low temperatures.

However, in high-temperature environments of 250℃ and above, silicone rubber is prone to thermal oxidative degradation, leading to the breakage of polymer main chains, shedding of side groups, accompanied by small molecule volatilization and destruction of cross-linked structures. This results in weight loss and decreased mechanical properties, seriously restricting its service life under extreme working conditions. How to improve the high-temperature stability of silicone rubber has become a research hotspot in the field of materials.

Fumed titanium dioxide (TiO₂) has potential as a functional additive and filler in the silicone rubber field due to its thermal stability, chemical inertness and nano-effects.

Among them, NT-50 prepared by the gas-phase method has broad application prospects in the silicone rubber field with the advantages of small particle size, good dispersibility and high surface activity.

Technicians from HIFULL explored the effect of NT-50 on improving the high-temperature stability of silicone rubber by comparing the changes in weight retention rate between high-temperature rubber, room-temperature rubber and liquid rubber with and without NT-50 under thermal storage conditions at 250℃.

HIFULL® NT-50

HIFULL NT-50 is fumed titanium dioxide (TiO2) prepared by the pyrolysis process. It has ultra-fine particle size, high purity, high specific surface area, and a unique combination of anatase and rutile mixed crystal structure. This product is applied in the field of catalysis and photocatalysis, it can also be used as an effective UV filter.

Technicians selected three typical silicone rubbers: high-temperature rubber, room-temperature rubber and liquid rubber, and prepared experimental group samples with 1.5% NT-50 added and blank group samples respectively. All samples were thermally stored in a constant temperature environment of 250℃, weighed regularly, and the weight retention rate was calculated (weight retention rate = weight after thermal storage / initial weight × 100%), and the curve of weight retention rate changing with thermal storage days was drawn.

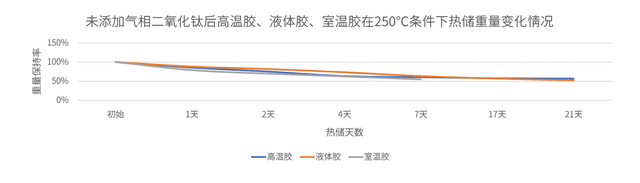

In the weight retention rate curve of silicone rubber without NT-50 added, the room-temperature rubber had a weight loss exceeding 40% after 7 days, and the rubber powdering experiment was terminated. For high-temperature rubber and liquid rubber, the weight loss reached 50% after 21 days, and the test was terminated due to rubber powdering.

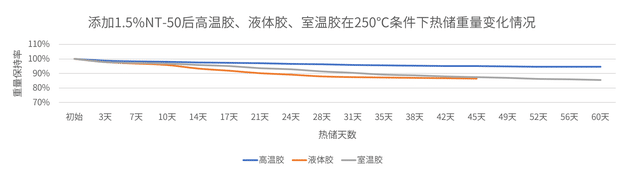

In the weight retention rate curve of silicone rubber with 1.5% NT-50 added, the weight loss of room-temperature rubber, high-temperature rubber and liquid rubber was within 5% after 7 days, and even did not exceed 15% after 60 days. The weight retention rate of the three types of rubber remained above 85% within 60 days, indicating that the addition of NT-50 effectively inhibited the thermal oxidative degradation process and significantly improved the high-temperature stability of silicone rubber.

The improvement of high-temperature stability of silicone rubber by NT-50 is mainly reflected in three aspects:

Physical barrier effect: NT-50 particles form a dense network structure in the silicone rubber matrix. On the one hand, it hinders the penetration of corrosive media such as oxygen and water vapor, reducing the occurrence of thermal oxidation reactions; on the other hand, it inhibits the volatilization of small molecules produced by the thermal decomposition of silicone rubber, reducing weight loss.

Free radical scavenging effect: As a semiconductor material, the surface electron pairs of NT-50 can capture free radicals generated by thermal degradation, terminate the free radical chain reaction, and fundamentally inhibit the oxidative degradation of materials.

Thermal conductivity optimization: The high thermal conductivity of NT-50 can improve the uniformity of thermal distribution of silicone rubber, reduce accelerated degradation caused by local overheating, make heat diffuse more efficiently, and delay the overall thermal aging process.

Fumed titanium dioxide NT-50 effectively inhibits the high-temperature thermal oxidative degradation of silicone rubber, providing a feasible solution for improving its service life in extreme environments.

From the perspective of industrial application, silicone rubber added with NT-50 can be further expanded to fields requiring harsh high-temperature resistance such as aerospace engine sealing, new energy vehicle battery packaging, and high-end electronic equipment heat dissipation. It solves the pain point of “easy aging at high temperature” of traditional silicone rubber, is expected to build a more efficient thermal stability system, promote the upgrading of silicone rubber materials towards higher temperature, more reliable and longer-acting directions, and provide key material support for the development of high-end manufacturing industry.