How to Select Hydrophilic or Hydrophobic Fumed Silica for Target Performance

In the fields of fine chemicals and materials science, fumed silica, as an important functional filler, has application performance largely determined by the selection of its surface properties. Although hydrophobic fumed silica is derived from modifying hydrophilic fumed silica, due to differences in surface characteristics, each plays irreplaceable role in different areas.

Especially with the continuous development of industrial technology, precisely modified hydrophobic fumed silica has become a key material for solving many specialized technical problems. In practical applications, how do the characteristic differences between hydrophilic and hydrophobic fumed silica affect their applications?

Hydrophilicity and Hydrophobicity: Fundamental Differences and Technological Evolution

Hydrophilic fumed silica surfaces are rich in silanol groups (-OH), possessing strong polarity and hygroscopicity, enabling interaction with water molecules through hydrogen bonding, thereby facilitating easy dispersion in aqueous systems. This property makes it widely used in coatings, pharmaceuticals, food, and other industries as a thickener, anti-settling agent, or anti-caking agent.

Common Application

However, in highly polar organic systems or moisture-sensitive environments, hydrophilic fumed silica tends to absorb moisture and form clumps, resulting in decreased dispersibility and stability issues for the product.

To overcome these limitations, hydrophobic fumed silica was developed. Through surface modification technologies such as silanization and silylazane treatment, the silanol groups (-OH) on the hydrophilic surface are replaced with non-polar groups (e.g., dimethylsiloxane, alkyl chains), significantly reducing surface polarity, endowing it with hydrophobicity and organic compatibility.

This modification not only reduces hygroscopicity but also improves dispersibility and rheological control in organic media. Notably, hydrophobic treatment is not merely “masking” polarity but involves molecular design to achieve controlled adjustment of surface energy, adapting to systems with varying polarities.

Property

Polarity Matching: Application Selection of HIFULL® Hydrophilic/Hydrophobic Fumed Silica

The core advantage of hydrophilic/hydrophobic fumed silica lies in its compatibility with systems of different polarities. According to the principle of polarity matching, materials with lower surface energy disperse more easily in low-polarity media. At the same time, medium-to-high-polarity systems require fillers with moderate polarity to balance interaction forces. Specifically:

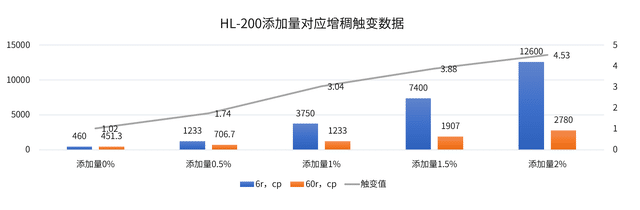

Non-polar systems: Such as methyl organosilicon, PVC, aromatic/aliphatic hydrocarbons (e.g., butyl, styrene), and non-polar solvents (e.g., THF), require adaptation to HIFULL® hydrophilic fumed silica like HL-150, HL-200, HL-300, HL-380.

Low-polarity systems, Such as MS Polymer, STP-E, polyacrylates, polysulfides, etc., with weaker intermolecular forces, necessitate the use of HIFULL® hydrophobic fumed silica with extremely low surface energy, such as HB-151, HB-152. These products, typically deeply alkylated, can effectively interact with the matrix through van der Waals forces, providing efficient thickening, thixotropy, and reinforcement.

Medium-polarity systems: Such as polyurethanes, polyols, polyamides, etc., containing a certain number of polar groups (e.g., ester, amide bonds) in their molecular structures. Hydrophobic fumed silica suitable for these systems should have moderate polarity, often achieved through partial alkylation or phenyl modification, balancing hydrogen bonding interactions and steric stabilization with the matrix.

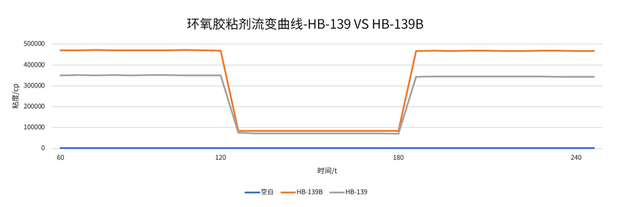

High-polarity systems: Such as epoxy resins, vinyl resins, amines, cyanoacrylates, isocyanates (MDI, TDI), and polar solvents (alcohols, ketones, esters), which are highly polar and often chemically reactive. These systems require hydrophobic products retaining some polar sites on the surface, avoiding excessive agglomeration while participating in interfacial interactions through residual silanol groups or designed polar functional groups, even promoting crosslinking reactions.

It’s worth noting that within the same system, there may be polarity gradients and variations, necessitating dynamic adjustment of the type of hydrophobic silica based on specific formulations. For instance, in epoxy resins, hydrophobic fumed silica not only enhances rheology but also improves corrosion resistance by reducing moisture permeability, and enhances dielectric properties and mechanical wear resistance through microstructural formation.

Performance Optimization: Structural Design Beyond Hydrophobicity

The R&D and production of HIFULL® hydrophobic fumed silica now extend beyond mere surface chemical modification to include morphology and structure control. For example, by controlling aggregated structures and pore distribution, products with high specific surface area and low bulk density can be obtained, providing more efficient rheological control at the same addition level.

Property

These structurally modified hydrophobic fumed silica exhibit outstanding performance in silicone rubber, sealants, and high-performance coatings: acting as both thixotropic agents to prevent sagging and reinforcing agents to improve the tear and wear resistance of elastomers.

In practical applications, the selection of HIFULL® hydrophobic fumed silica must comprehensively consider system polarity, process conditions, and final performance requirements. With the advancement of nanotechnology and materials genomics projects, the modification of fumed silica is evolving towards precision and functionality.

The choice between hydrophilic and hydrophobic fumed silica essentially represents a precise alignment between surface science and application needs. Through polarity gradient design, hydrophobic products achieve full-spectrum adaptation from low to high-polarity systems, becoming an indispensable “industrial seasoning” in high-performance material development. Only by deeply understanding its modification principles and application scenarios can one make wise choices amidst this affinity-repulsion dichotomy, unlocking the maximum potential of this new material.

In the future, with the deepening of modification technologies and the accumulation of application data, the selection of fumed silica will transition from experiential to scientific, from general-purpose to customized, ultimately becoming a sharp tool driving industrial innovation.