Stable Haze but Declining Transmittance: Using HIFULL® Nano Al₂O₃ in Ceramics

Ceramic materials are widely used in many industries such as electronic equipment, aerospace, and biomedicine due to their excellent heat resistance, corrosion resistance, and mechanical properties. Ceramics are made from powder raw materials through molding and high-temperature sintering. Traditional ceramics have poor light transmittance due to numerous internal grain boundaries, pores, and impurities.

HIFULL® nano aluminium oxide, as an ultrafine powder synthesized by gas-phase methods, has special properties such as good purity, chemical stability, and positive surface charge. Additionally, it is chemically stable and highly hard. In the preparation of ceramic materials, nano alumina can serve as a sintering aid to accelerate the densification process.

Altering the microstructure of ceramics affects sintering, optical, and mechanical properties, thereby enhancing the comprehensive application performance of ceramics.

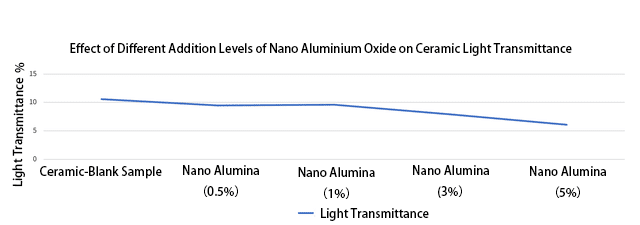

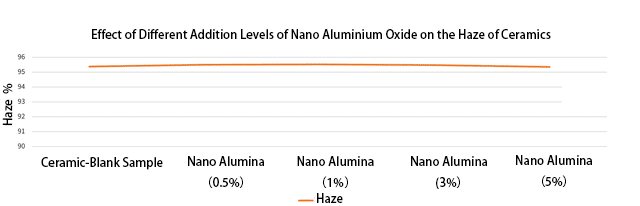

To further verify the effect of HIFULL® nano aluminium oxide addition on the transmittance and haze of ceramics, researchers at Hubei Huifu Nanomaterial Co., Ltd. used ceramics without added nano alumina as control samples, and those with added nano alumina at mass fractions of 0.5%, 1%, 3%, and 5% as experimental samples. By comparing the transmittance and haze under different addition amounts, they aimed to reveal the optical effects of nanomaterials in ceramic applications.

And HIFULL® technicians tested the transmittance. The data showed that the transparency of ceramic materials decreased with increasing nano alumina content. Without adding nano alumina, the transmittance of ceramic materials was around 10%. After adding 0.5% nano alumina, the transmittance dropped below 10%. With further increases in the addition amount, the final transmittance continuously decreased to 6%.

It is evident that without adding HIFULL® nano alumina, the internal microstructure of ceramics is relatively uniform, with fewer scattering sources such as pores and impurities, resulting in minimal light scattering loss, reflecting the optical characteristics under basic conditions. When nano alumina is added, theoretically, it should promote sintering, but in practice, it often forms small aggregates due to uneven dispersion, becoming centers for light scattering, thus slightly reducing transmittance. A small addition amount has limited interference with the microstructure and transparency. However, when the addition amount is increased, excessive particles hinder sintering densification, leading to increased porosity, further exacerbating scattering, and reducing transmittance.

The technicians then tested the haze of the ceramics. They found that the haze remained largely stable (95%-96%) across various addition amounts. This is because nano alumina’s chemical stability does not introduce significant strong scattering impurities (such as substances with high refractive index differences) at the interface with the ceramic matrix. Moreover, the size and distribution of aggregates do not drastically change the scattering mode, so the light scattering characteristics remain relatively consistent, resulting in no significant fluctuations in haze. This reflects that the addition amount of nano alumina has little impact on haze, which remains stable.

The addition of HIFULL® nano alumina significantly affects the transmittance of ceramics. Higher addition amounts lead to lower transmittance, mainly due to aggregate scattering and hindered densification. Haze, however, is less affected by the addition amount, remaining relatively stable due to microstructural and particle characteristics. This indicates that controlling the addition amount and dispersibility of nano alumina is key to optimizing ceramic transparency.

Learn More: The Effect of Fumed Silica on Improving The Transparency of Ceramics

HIFULL® research reveals the influence rules of nano alumina on transparency, providing a basis for optimizing ceramic preparation processes. Future efforts could focus on nanoparticle dispersion technologies (such as surface modification and ultrasonic-assisted dispersion) to reduce aggregation effects. Additionally, exploring the synergistic effects of multiple additives could further enhance the performance of transparent ceramics.

From the perspective of industrial upgrading, high-performance transparent ceramics can promote the miniaturization and efficiency of optical devices, aiding innovation in new energy (such as transparent conductive ceramics for photovoltaics) and biomedical (optical ceramic devices) industries.

As a critical additive, optimizing the application of HIFULL® nano aluminium oxide will facilitate the industrialization process of transparent ceramics, revitalizing traditional ceramic materials in modern high-tech fields. It provides material support for breaking through technical bottlenecks and achieving high-end manufacturing upgrades, embodying the technological value of “innovating at the micro-nano scale to drive material leaps.”