The Influence of Hydrophilic Fumed Silica on the Thickening and Thixotropic Properties of UV-Curable Wood Coatings

In the field of coatings, UV wood coatings have been widely used in wood finishing such as furniture and floors due to their advantages, including fast curing speed, high hardness, wear resistance, and environmental friendliness. As a key performance, the thixotropy of coatings significantly affects their application properties.

Hydrophilic fumed silica, as a commonly used additive in coatings, has a significant impact on the thickening and thixotropy of UV wood coatings depending on its dosage. This article focuses on HIFULL hydrophilic fumed silica HL-200, exploring in depth the relationship between its addition amount and the thickening/thixotropy behavior of UV wood coatings.

Coatings with good thixotropy exhibit higher viscosity at rest, effectively preventing sagging, when subjected to shear forces (such as brushing or spraying), the viscosity rapidly decreases, facilitating application operations, after application, the viscosity quickly recovers, ensuring uniformity and integrity of the coating film.

What is Hydrophilic fumed silica?

Hydrophilic fumed silica, also known as hydrophilic vapor-phase silicon dioxide, is an important inorganic functional powder material. It features large specific surface area, high surface energy, and excellent chemical stability.

In coatings, hydrophilic fumed silica mainly forms hydrogen-bonded network structures through interactions among surface hydroxyl groups, thereby achieving thickening, anti-settling, and thixotropic effects. This unique mechanism makes it widely applicable in the coating industry.

What are UV wood coatings?

UV wood coatings are coatings that use ultraviolet light irradiation to initiate curing reactions. Compared with traditional solvent-based coatings, UV wood coatings possess advantages such as rapid curing, high production efficiency, and low VOC (volatile organic compound) content. They primarily consist of resins, reactive diluents, photoinitiators, pigments, fillers, and additives. During the curing process, photoinitiators absorb ultraviolet energy and generate free radicals or cations, triggering polymerization reactions of resins and reactive diluents, thus forming hard, wear-resistant coating films.

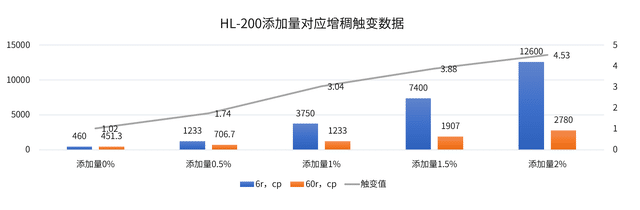

For this purpose, researchers from Hubei Huifu Nanomaterial Co., Ltd. experimentally investigated the influence of different amounts of hydrophilic fumed silica HL-200 on the thickening and thixotropy of UV wood coatings. The experiments utilized a rotational viscometer to measure coating viscosity at speeds of 6 rpm and 60 rpm, respectively, and calculated the corresponding thixotropy values. The experimental data are presented in the table below:

Viscosity Trend:

From the experimental data, it can be observed that as the addition amount of HL-200 increases, the viscosity of UV wood coatings measured at both 6 r/min and 60 r/min shows a rising trend. Notably, under low-speed conditions (6 r/min), the increase in viscosity is particularly pronounced.

For example, when the addition amount increased from 0% to 2%, the viscosity at 6 r/min rose from 460 cp to 12,600 cp, while the viscosity at 60 r/min increased from 451.3 cp to 2,780 cp. These results indicate that HL-200 exerts obvious thickening effects on UV wood coatings, especially more significantly under lower shear rates.

Thixotropy Value Change:

The thixotropy value, defined as the ratio of viscosity measured at low shear rate to that obtained at high shear rate, serves as a crucial indicator for evaluating coating thixotropy. The experimental findings reveal that with increasing addition amounts of HL-200, the thixotropy value increases substantially, ranging from 1.02 up to 4.53. This demonstrates clearly that incorporating HL-200 greatly enhances the thixotropic characteristics of UV wood coatings, enabling them to achieve higher viscosity under low-shear conditions and relatively lower viscosity under high-shear conditions, thereby improving sag resistance and settling prevention capabilities.

Learn More: HL-200 Properties and Functional Applications

Viscosity Difference Analysis:

Additionally, attention should be paid to the viscosity differences observed at 6 r/min versus 60 r/min across various addition levels. As the addition amount rises, these differences become increasingly apparent.

For instance, at 1% addition, the viscosity at 6 r/min reaches 3,750 cp, while at 60 r/min, it measures only 1,233 cp, resulting in a difference of 2,517 cp. At 2% addition, this discrepancy further expands to 9,820 cp. Such noticeable variance reflects the substantial influence of HL-200 on the rheological behavior of UV wood coatings, particularly highlighting its effective regulation capacity over viscosities under diverse shear rate conditions.

Through the above experimental research examining how varying quantities of HL-200 affect the thickening and thixotropy of UV wood coatings, the following conclusions can be drawn:

Looking ahead, alongside continuous advancements within the coating industry, demands placed upon coating performance will steadily intensify. Given its effectiveness as a thickening and thixotropic agent, HL-200 holds promising prospects within UV wood coating applications. By further optimizing addition amounts and formulation designs, it becomes possible to better meet varied operational requirements and desired end-product characteristics, driving broader utilization and development potential for UV wood coatings.

In summary, HIFULL® hydrophilic fumed silica HL-200 exerts considerable influence upon the thickening and thixotropy properties of UV wood coatings. Through scientifically rational formulation design, coating performance and quality can be efficiently improved, injecting fresh vitality into ongoing progress within the coating sector.