How Much Hydrophilic Fumed Silica Is Needed to Adjust Waterborne Wood Coatings from High Gloss to Matte?

In the modern coatings industry, waterborne wood coatings have gradually become mainstream due to their significant advantages, such as environmental friendliness, safety, and low toxicity. Among various types of waterborne wood coatings, acrylic waterborne wood coatings are especially favored by consumers and manufacturers for their excellent weather resistance, water resistance, and mechanical properties.

In practical applications, Gloss is a key indicator for evaluating coating film glossiness, which directly affects the product’s appearance and texture. As a functional additive in coatings, fumed silica not only offers outstanding thickening and thixotropic properties, anti-settling performance, anti-sagging characteristics, and corrosion/wear resistance, but also influences the glossiness of the coating film when added above a certain threshold.

Therefore, balancing the dosage of fumed silica in acrylic waterborne wood coatings becomes particularly critical. While high gloss conveys luxury, matte and semi-matte finishes offer a soft, refined texture and better highlight the natural grain of wood, equally essential qualities.

Paints & Coatings

HIFULL researchers conducted experiments using HIFULL® HL-260 hydrophilic fumed silica. They thoroughly dispersed and mixed HL-260 into a domestic acrylic waterborne wood coating, applied uniform films onto wooden substrates, and measured the gloss at a 60° angle using a gloss meter.

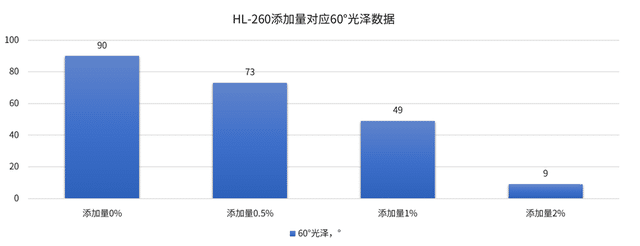

This experiment primarily investigated the effect of hydrophilic fumed silica HL-260 dosage on the 60° gloss of acrylic waterborne wood coatings. The technical team prepared a blank sample with 0% addition and three experimental samples with dosages of 0.5%, 1%, and 2%, respectively, and precisely measured the gloss of each coating film, obtaining the following data:

0% hydrophilic fumed silica addition

The experimental results clearly show that as the dosage of hydrophilic fumed silica HL-260 increases, the 60° gloss of the acrylic waterborne wood coating exhibits a significant downward trend. At 0% addition, the coating film’s 60° gloss reached as high as 90, indicating that the acrylic waterborne wood coating without any matting agent delivers high gloss, suitable for decorative applications requiring a glossy finish.

0.5% hydrophilic fumed silica addition

When the dosage increased to 0.5%, the gloss rapidly dropped to 73, a decrease of 18.8%. This result demonstrates that even at a relatively low dosage, hydrophilic fumed silica HL-260 can significantly affect the coating film’s gloss, effectively reducing it and producing a noticeable matting effect.

1% hydrophilic fumed silica addition

As the dosage further increased, the gloss continued to decline. At 1% addition, the gloss decreased to 49, representing a 45.5% reduction compared to the 0% sample, and the matting effect became even more pronounced. This indicates a positive correlation between the dosage of HL-260 and its matting efficiency: the higher the dosage, the stronger the matting effect.

2% hydrophilic fumed silica addition

At a dosage of 2%, the gloss sharply dropped to 9, a dramatic 90% reduction, approaching a virtually non-glossy state. This result confirms that hydrophilic fumed silica HL-260 possesses powerful matting capability at high dosages, capable of reducing the coating film’s gloss to an exceptionally low level, thereby meeting application scenarios with stringent matting requirements.

Overall, hydrophilic fumed silica HL-260 has a significant influence on the matting performance of acrylic waterborne wood coatings. As its dosage increases, the matting effect intensifies progressively, allowing for precise control over a wide range of gloss levels, from high gloss to nearly zero gloss.

As a multifunctional additive, hydrophilic fumed silica HL-260 not only provides rheological control, anti-settling, and anti-sagging benefits within coating systems but also markedly reduces the gloss of acrylic waterborne wood coatings. With increasing dosage, its thickening, thixotropic, anti-settling, and anti-sagging effects become stronger, while its matting performance simultaneously enhances, allowing accurate gloss adjustment across the full spectrum from high gloss to matte.

With rising environmental awareness and continuous advancements in coating technologies, the application prospects of fumed silica in acrylic waterborne wood coatings will become even broader. HIFULL® technical team will further investigate the interactions between hydrophilic/hydrophobic fumed silica and other coating components, optimize formulations, improve the comprehensive performance of coating films, and expand application fields, making greater contributions to the sustainable development of the coatings industry.