The Disruptive Impact of Fumed Nanomaterial Dispersion Control on UV Coatings

The Disruptive Impact of Fumed Nanomaterial Dispersion Control on UV Coatings

Fumed silica can provide excellent thickening and thixotropic properties, anti-sagging, and anti-settling effects in coatings, while fumed alumina can improve the powder coating deposition rate and spraying efficiency. However, for fumed nanomaterials to perform their functions and roles in coatings, good dispersibility is essential. Poor or inadequate dispersion is one of the key factors limiting the performance of fumed nanomaterials.

To investigate the effect of fumed nanomaterial dispersibility on UV coating performance, technicians from Hubei Huifu Nanomaterial Co., Ltd. explored the optimal dispersion parameters by varying dispersion time and rotational speed of dispersion equipment. They also studied the influence of different dispersion levels on the viscosity, thixotropic value, particle state, gloss, haze, light transmittance, pencil hardness, and abrasion value of UV coatings.

It was found that the dispersion degree of fumed nanomaterials significantly affects the performance of UV coatings. Proper dispersion processes can fully leverage the advantages of fumed nanomaterials and improve the overall performance of UV coatings.

UV coatings

UV coatings are coatings that cure under UV radiation. They offer advantages such as fast curing speed, room-temperature curing, energy savings, reduced production space, environmental friendliness, and enhanced product performance.

Fumed silica

Fumed silica is an extremely important ultra-fine inorganic material. It features very small particle size, large specific surface area, strong surface adsorption, high surface energy, high chemical purity, and good dispersibility. It exhibits excellent dispersion, stability, reinforcement, thickening, and thixotropic properties.

In UV-curable coatings, fumed silica provides good thickening and thixotropic behavior, excellent matting effects, and improved hardness, particularly significantly enhancing the coating’s abrasion resistance.

fumed alumina

fumed alumina is also an important ultra-fine inorganic new material. It is mainly used in coatings to improve the flowability of powder coatings. It can form a movable layer on the surface of powder coating raw materials, preventing moisture absorption and caking. At the same time, its self-charging characteristic with positive friction helps improve the spraying performance of powder coatings and increases the deposition rate.

Experimental process

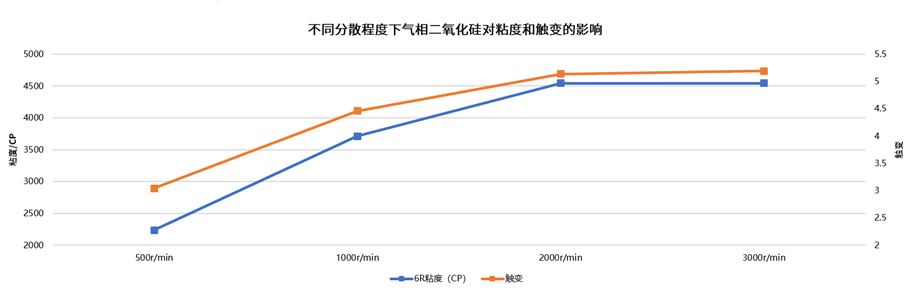

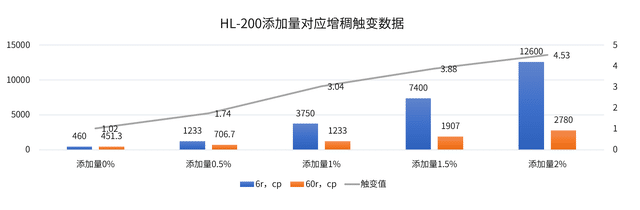

First, technicians from Hubei Huifu Nanomaterial Co., Ltd. added the same amount of hydrophilic fumed silica HL-200 into a UV coating using a high-speed disperser, and dispersed it at speeds of 500 r/min, 1000 r/min, 2000 r/min, and 3000 r/min for 30 minutes.

The viscosity and thixotropy of the four groups of samples were then tested. The results showed that as the dispersion process of fumed silica intensified, the viscosity of the UV-curable coating continuously increased, and the thixotropic value kept rising, reaching the optimal state at 3000 r/min, with a viscosity of 4543 Pa·s and a thixotropic value of 5.

However, as the dispersion speed increased, the upward trend in viscosity and thixotropy of the UV coating gradually slowed and reached a critical value. Further increases in speed no longer affected the thickening and thixotropic properties, and viscosity and thixotropy stabilized.

Subsequently, the technicians applied the above UV coatings and observed after curing that when the dispersion speed was below 1000 r/min, the coated film surface showed obvious granularity and fragmentation. At speeds above 2000 r/min, the film surface was smoother.

Overall, to achieve the optimal viscosity, thixotropy, and particle state of the UV coating, the dispersion conditions should be greater than 2000 r/min for 30 minutes.

| Coating performance | blank | HL-200 | Other Brand Fumed silica | Aluna-100 |

|---|---|---|---|---|

| Gloss (°) | 85 | 71 | 73 | 82 |

| Haze (%) | 0.9 | 1.82 | 1.96 | 2.45 |

| Light transmittance (%) | 86..4 | 85.3 | 84.5 | 85.8 |

| Hardness (pencil hardness) | 4H | 5H | 5H | 6H |

| Abrasion value (g) | 0.0746 | 0.0408 | 0.0413 | 0.0375 |

At the same time, with a 1.5% powder additive amount, technicians conducted comprehensive experiments and comparisons on the gloss, haze, light transmittance, hardness, and abrasion value of UV coating films for blank samples, HL-200, a competing hydrophilic fumed silica product, and fumed alumina Aluna-100.

In the above experiments, compared to the blank sample, HL-200 and the competing product had a low impact on light transmittance and could improve the pencil hardness of the UV coating. The differences in matting, hardness, and abrasion resistance between the two were not significant. When comparing different fumed nanomaterials, the addition of fumed silica reduced the gloss of the coating film, while fumed alumina Aluna-100 had a lower impact on the gloss of the UV coating. It also provided greater improvement in pencil hardness, less mass loss in abrasion value, and better enhancement in abrasion resistance.

conclusion

Fumed nanomaterials, such as fumed silica and fumed alumina, have significant application value in UV coatings and can markedly improve the performance of UV coatings. However, their dispersion degree in the coating crucially influences the coating’s performance. Good dispersion allows nanomaterials to be uniformly distributed in the coating system, fully leveraging their unique properties to enhance the coating’s viscosity and thixotropy, improve particle state, and boost the gloss, light transmittance, pencil hardness, and abrasion resistance of the coating film.

Conversely, poor dispersion can lead to abnormal viscosity, defects in the coating film, reduced gloss and light transmittance, and unstable hardness and abrasion resistance. Therefore, when applying fumed nanomaterials in UV coatings, it is essential to emphasize the research and optimization of dispersion processes, adopt suitable dispersion equipment and dispersing agents, and ensure that nanomaterials achieve good dispersion in the coating. This will fully utilize the performance-enhancing effects of fumed nanomaterials on UV coatings and promote the development of the UV coating industry.