Hydrophobic Fumed Silica Application in PV Encapsulant Films

Amid the vigorous development of the photovoltaic industry, the performance and stability of PV modules are of paramount importance. PV encapsulant, as a critical packaging material ensuring the reliable operation of PV modules, has garnered significant attention for its performance optimization.

Fumed silica, a uniquely functional additive, particularly hydrophobic fumed silica, exerts a complex and crucial influence on the properties of PV encapsulants. In-depth research on their relationship is highly significant for improving the quality of PV modules.

PV encapsulant refers to a category of adhesives and sealing materials specifically used in the production process of solar PV modules. Its primary functions within PV modules include: encapsulating and protecting solar cells, isolating them from external moisture, oxygen, dust, and other impurities to prevent corrosion and extend the service life of the modules; ensuring structural stability through strong adhesion that securely bonds the cells with frames, backsheets, and other components; and providing certain electrical insulation properties to guarantee electrical safety during power generation.

Fumed silica is primarily produced through the high-temperature hydrolysis of halosilanes (such as silicon tetrachloride) in a hydrogen-oxygen flame. During this process, the halosilane rapidly hydrolyzes at high temperatures to form primary silica particles. These primary particles then collide and agglomerate to form aggregates with a three-dimensional network structure. Its structural characteristics include an extremely small particle size, typically between 7–40 nm, and a large specific surface area, which can reach 50–400 m²/g. This unique microstructure imparts many special properties to fumed silica.

Hydrophilic fumed silica has a surface rich in silanol groups (Si–OH), enabling interaction with water and other polar substances, and it disperses well in polar solvents. In contrast, hydrophobic fumed silica is produced by chemically modifying the surface of hydrophilic fumed silica. This process introduces organic groups (such as methyl or vinyl groups), covering some of the silanol groups, thereby reducing surface polarity and imparting hydrophobicity, which leads to better dispersion in non-polar or weakly polar systems.

Hydrophobic Fumed Silica

how does hydrophobic fumed silica perform in PV encapsulants?

Technicians from Hubei Huifu Nanomaterial Co., Ltd. conducted tests and validations through experiments.

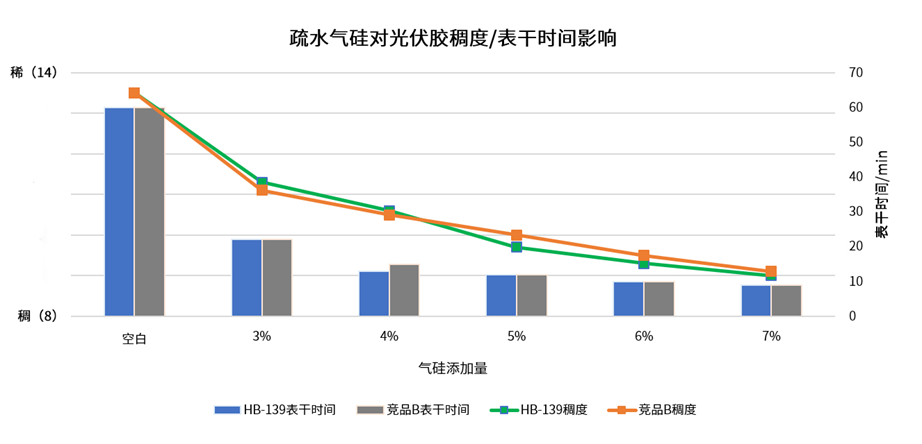

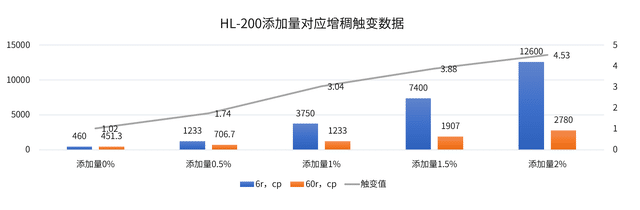

In consistency and surface drying tests, consistency affects the application process of the encapsulant, while surface drying time influences the curing effect after application.

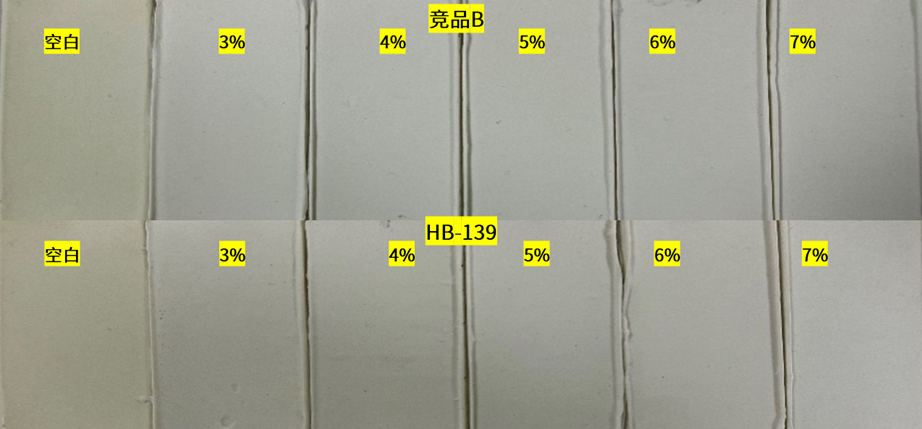

The technicians added hydrophobic fumed silica HB-139 and competing product B at ratios of 3%, 4%, 5%, 6%, and 7% to the PV encapsulant. As the addition amount of hydrophobic fumed silica increased, the consistency gradually increased, reducing fluidity, and the surface drying time gradually decreased.

In terms of consistency, at addition amounts of 3% and 4%, HB-139 showed higher consistency than competing product B, while at 5%, 6%, and 7%, HB-139 had lower consistency than competing product B. Regarding surface drying time, except at the 4% addition level where HB-139 dried faster than competing product B, the drying times were generally similar at other addition levels.

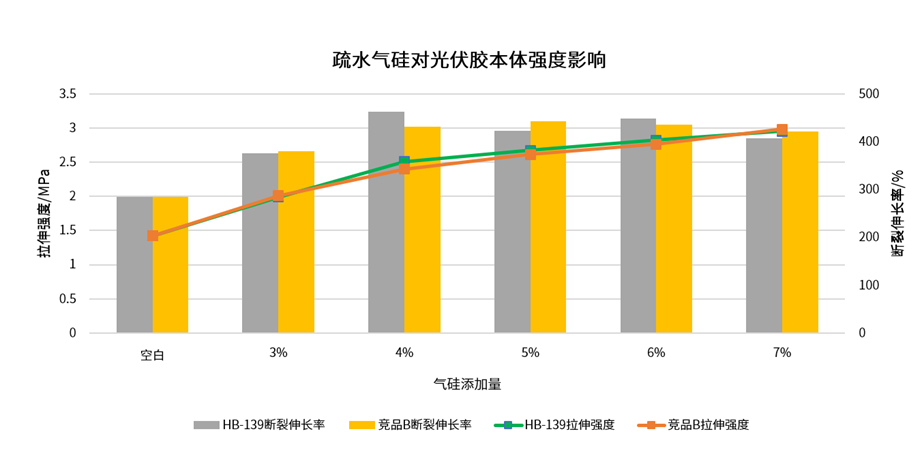

In tests evaluating the effect on the bulk strength of the PV encapsulant, as the addition amount of hydrophobic fumed silica increased, the elongation at break first increased and then decreased, while the tensile strength showed an increasing trend.

In elongation at break tests, at addition levels of 3% and 4%, HB-139 performed better. At 5%, 6%, and 7%, HB-139 and competing product B each had their advantages. In tensile strength tests, except at the 4% addition level, HB-139 exhibited higher tensile strength than competing product B at addition levels below 6%, but at 7%, HB-139’s tensile strength was lower than that of competing product B.

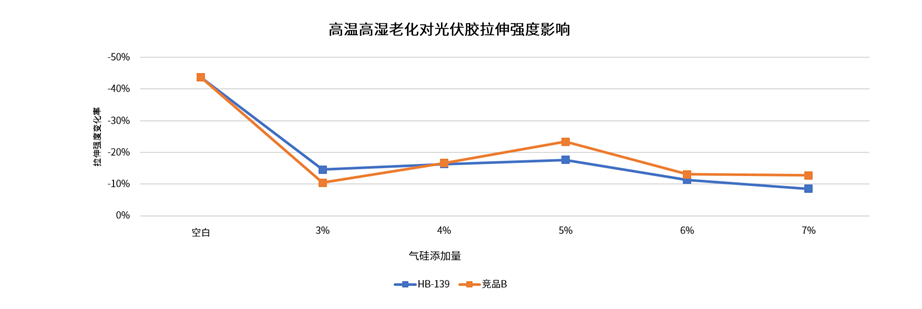

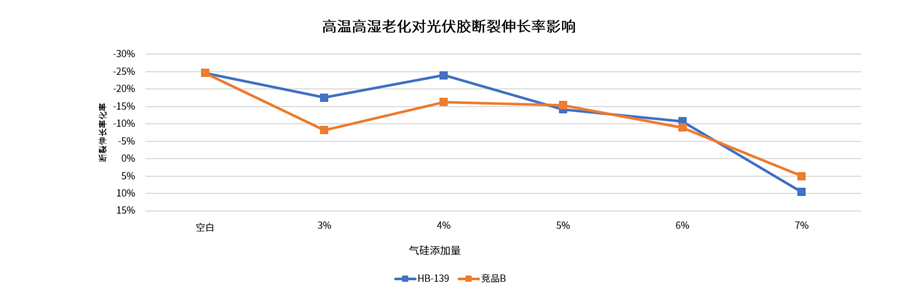

Under high-temperature and high-humidity aging conditions (85°C, 85% humidity, 1000 hours), the performance of HB-139 and competing product B was tested. Both showed similar bulk strength performance after aging, and the addition of hydrophobic fumed silica slowed the decline in tensile strength and elongation at break of the PV encapsulant.

In yellowing resistance tests, as the addition amount of hydrophobic fumed silica increased, the resistance to yellowing under high temperature and humidity improved. This is mainly attributed to the photochemical stability of hydrophobic fumed silica and its nano-barrier effect, which hinders the diffusion of oxygen and water molecules, thereby inhibiting photo-oxidation reactions.

Hydrophobic fumed silica significantly enhances the reliability of PV encapsulants in high-temperature and high-humidity environments by strengthening the cross-linking network, improving weatherability, and enhancing mechanical properties. As the photovoltaic industry advances toward higher efficiency and longer service life, the application of hydrophobic fumed silica in PV encapsulants will become one of the key technologies for improving module quality.