HIFULL®Hydrophilic Fumed Silica in PV Adhesives

Photovoltaic(PV) adhesives are key encapsulation materials for solar photovoltaic modules, directly impacting their reliability and service life. Fumed silica can be used as an additive to enhance the performance of PV adhesives.

In applications, the performance of hydrophilic fumed silic and hydrophobic fumed silica differs significantly, depending on the additive ratio and product quality.

PV adhesives are primarily used for bonding and sealing solar photovoltaic modules and cure at room temperature via moisture in the air. They offer a range of key properties, including:

PV adhesives are not only used for sealing PV modules but also for coating protection of electronic components, potting small components, and general bonding and industrial sealing of metals, glass, plastics, etc. Since PV modules are mostly used outdoors, PV adhesives must also exhibit good resistance to UV exposure, yellowing, mechanical shock, thermal shock, and vibration.

Hydrophilic fumed silica properties

Hydrophilic fumed silica is produced by hydrolyzing volatile chlorosilanes in a hydrogen-oxygen flame. It appears as a white, fluffy powder and primarily consists of high-purity amorphous silica.

This product is non-toxic, odorless, pollution-free, and high-temperature resistant. It features extremely small particle size, large specific surface area, strong surface adsorption capacity, and high surface energy, giving it excellent thermal stability, high insulation, chemical inertness, and high purity. Its unique microstructure allows it to disperse in water and be wetted by water.

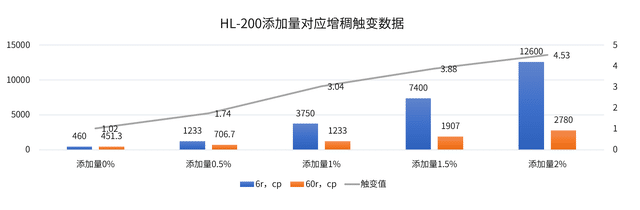

Based on these properties, hydrophilic fumed silica demonstrates unique functionalities in various fields, such as regulating the rheology and thixotropy of liquid systems, reinforcing silicone rubber, thickening non-polar liquids, and serving as a flow aid in food and industrial powders.

Experimental process

To further investigate the impact of the dosage and quality differences of hydrophilic fumed silica on PV adhesives, technicians from Hubei Huifu Nanomaterial Co., Ltd. conducted multiple experiments and data verifications.

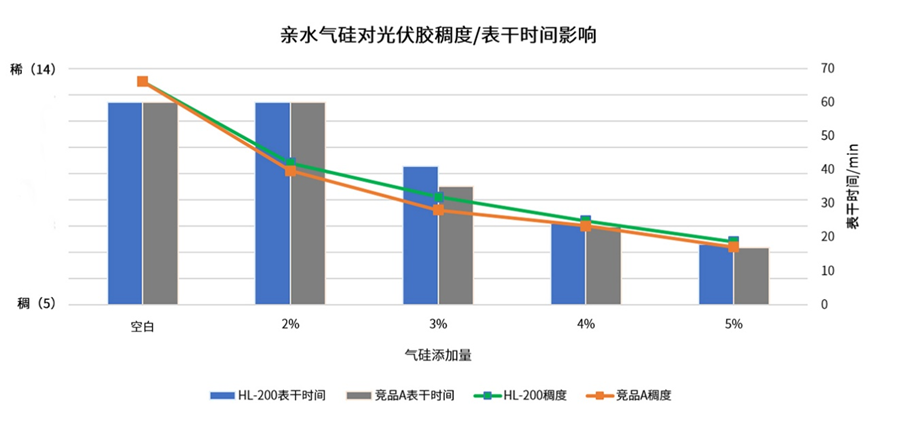

In tests on the consistency and surface drying time of PV adhesives with hydrophilic fumed silica, both HL-200 and Competitor A showed increased consistency as the dosage increased from 2% to 5%. However, at the same dosage, HL-200 exhibited a higher consistency increase than Competitor A.

In terms of surface drying time, as the dosage of fumed silica increased, the surface drying time of the PV adhesive shortened. At a 3% dosage, HL-200 had a slightly longer drying time compared to Competitor A, while at other dosages, the drying times were relatively consistent.

In tests on the bulk strength of PV adhesives with hydrophilic fumed silica, both HL-200 and Competitor A showed increasing elongation at break and tensile strength as the dosage increased. In terms of elongation at break, HL-200 outperformed Competitor A at 2%, 3%, and 4% dosages but was slightly lower at a 5% dosage. Similarly, for tensile strength, HL-200 exhibited higher values at 2%, 3%, and 4% dosages but was slightly lower at a 5% dosage.

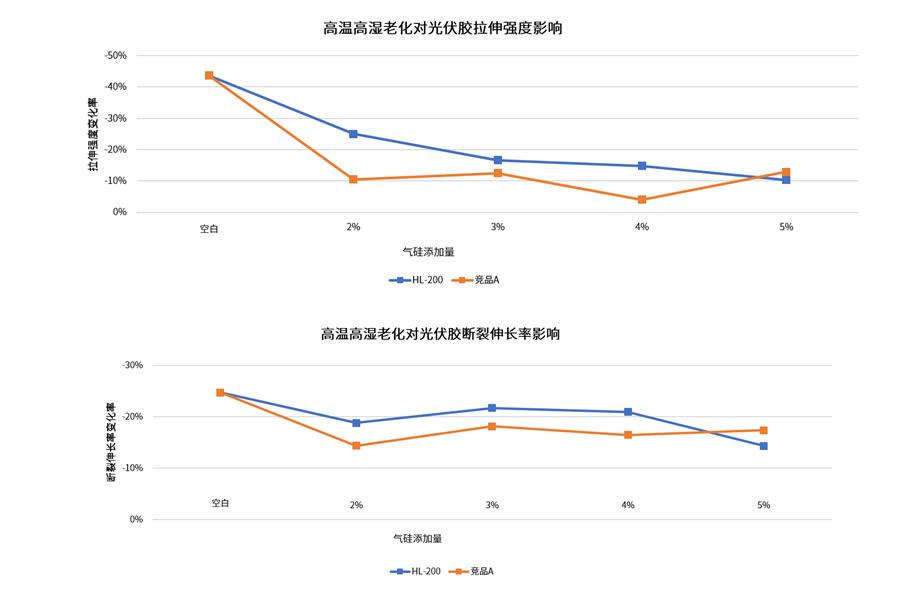

Under high-temperature and high-humidity aging conditions (85°C, 85% humidity, 1000 hours), the tensile strength of PV adhesives with different dosages of HL-200 and Competitor A was tested to compare changes before and after aging. The bulk strength performance of HL-200 and Competitor A after high-temperature and high-humidity aging was similar. The addition of hydrophilic fumed silica slowed the decline in tensile strength and elongation at break of PV adhesives after aging.

HIFULL® hydrophilic fumed silica has a multifaceted and significant impact on the performance of PV adhesives. By rationally controlling the dosage of hydrophilic fumed silica, key performance indicators such as consistency, surface drying time, bulk strength, and tensile strength and elongation at break under high-temperature and high-humidity conditions can be effectively optimized.

In future research and production, further exploration of the interaction mechanisms between hydrophilic fumed silica and PV adhesive systems is needed to develop higher-performance PV adhesive products, meet the evolving demands of the photovoltaic industry, and provide reliable technical references for the industry. It is recommended to optimize processes based on specific resin systems in practical applications to achieve the best comprehensive performance.

conclusion

Fumed nanomaterials, such as fumed silica and fumed alumina, have significant application value in UV coatings and can markedly improve the performance of UV coatings. However, their dispersion degree in the coating crucially influences the coating’s performance. Good dispersion allows nanomaterials to be uniformly distributed in the coating system, fully leveraging their unique properties to enhance the coating’s viscosity and thixotropy, improve particle state, and boost the gloss, light transmittance, pencil hardness, and abrasion resistance of the coating film.

Conversely, poor dispersion can lead to abnormal viscosity, defects in the coating film, reduced gloss and light transmittance, and unstable hardness and abrasion resistance. Therefore, when applying fumed nanomaterials in UV coatings, it is essential to emphasize the research and optimization of dispersion processes, adopt suitable dispersion equipment and dispersing agents, and ensure that nanomaterials achieve good dispersion in the coating. This will fully utilize the performance-enhancing effects of fumed nanomaterials on UV coatings and promote the development of the UV coating industry.