The Effect of Fumed Silica on Improving The Transparency of Ceramics

In the research and production of ceramic materials, transparency and haze are critical indicators for evaluating material quality and application value. Fumed silica, a unique inorganic nanomaterial, is gaining increasing attention in the ceramic field due to its ultrafine particle size, high specific surface area, and excellent dispersibility, particularly regarding its impact on ceramic transparency.

Fumed silica is produced via high-temperature hydrolysis of halosilanes in a hydrogen-oxygen flame, resulting in a white, amorphous nano-sized silica powder. It includes both hydrophilic and hydrophobic types, with the hydrophobic variant derived from surface modification of the hydrophilic form. Hydrophilic fumed silica can further be categorized into low-specific-surface-area and high-specific-surface-area grades based on its specific surface area. Its particles are at the nanoscale and rich in surface silanol (Si–OH) groups.

Ceramic materials refer to a class of inorganic non-metallic materials fabricated by shaping natural or synthetic compounds followed by high-temperature sintering. They exhibit high melting points, high hardness, excellent wear resistance, and oxidation resistance. While traditional ceramics prioritize mechanical properties, the growing demands from optical and electronic fields have significantly increased the need for transparent ceramics.

In practical ceramic applications, fumed silica serves as a high-performance nano-additive that markedly enhances mechanical strength, sintering behavior, optical performance, and microstructure of ceramics, thereby improving matrix toughness, lowering sintering temperature, and reducing sintering time.

But how do fumed silicas with different specific surface areas affect ceramic transparency and haze?

Researchers at Hubei Huifu Nanomaterial Co., Ltd. focused on the effects of low and high-specific surface area fumed silica at varying addition levels on ceramic transparency and haze, aiming to elucidate the underlying mechanisms and provide theoretical support for optimizing ceramic performance.

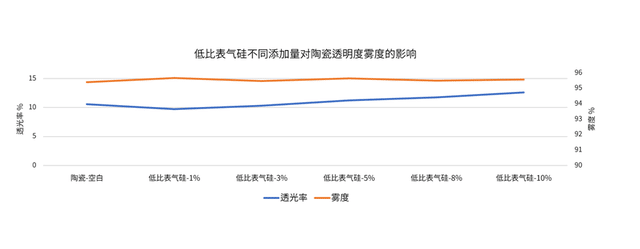

In the low specific surface area fumed silica experiment, technicians incorporated 1%, 3%, 5%, 8%, and 10% fumed silica into experimental ceramic samples, respectively, and tested their transmittance and haze against a blank sample. They observed that the orange haze curve remained relatively flat, with haze consistently around 96%, while the blue transmittance curve showed an overall upward trend, increasing from approximately 10% to about 12%. This indicates that adding low-specific-surface-area fumed silica moderately improved ceramic transmittance with minimal impact on haze.

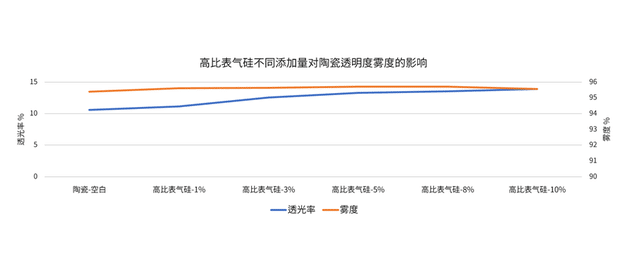

In the high specific surface area fumed silica experiment, technicians similarly added 1%, 3%, 5%, 8%, and 10% fumed silica to ceramic samples and measured transmittance and haze against the blank. The orange haze curve again remained stable at around 95.5%, while the blue transmittance curve rose more noticeably, from about 10% to roughly 14%.

Compared with low-specific-surface-area fumed silica, high-specific-surface-area fumed silica demonstrated a more pronounced enhancement in transmittance. This is attributed to its larger specific surface area and higher density of surface silanol groups, which, upon dispersion in the ceramic matrix, exhibit greater reactivity. This facilitates stronger interactions with ceramic particle surfaces during sintering, promoting particle rearrangement and densification, and more effectively eliminating pores.

So, how exactly does fumed silica enhance ceramic transparency while stabilizing haze?

1. Filling and Densification Effect

The nano-sized fumed silica particles can infiltrate the interstitial voids between ceramic grains. During the sintering stage, surface silanol groups on fumed silica can form hydrogen bonds or chemical bonds with functional groups on ceramic particle surfaces, enhancing interparticle bonding and mass transport. This accelerates the sintering process, leading to a denser green body. Original pores within the ceramic are partially filled or expelled with the assistance of fumed silica, and larger pores are reduced in size, thereby minimizing pore-induced light scattering.

2. Effective Suppression of Internal Light Scattering

In polycrystalline ceramics, grain boundaries are primary sources of light scattering. Conventional ceramics often contain amorphous phases or impurities at grain boundaries, causing significant refractive index mismatches between grains and boundaries and thus strong scattering.

When fumed silica is introduced into the ceramic system, it forms fumed silica–ceramic matrix interfaces that suppress the disordered growth of amorphous phases at grain boundaries. This promotes a more homogeneous, single-phase boundary structure, yielding smaller, more uniform grain sizes and smoother, more regular grain boundaries, collectively reducing light scattering caused by grain boundaries.

Through these mechanisms, fumed silica minimizes internal light-scattering centers in ceramics—primarily pores, followed by coarse grains and defective grain boundaries, enabling light to pass through the material more efficiently and thereby significantly enhancing transmittance.

Moreover, data analysis from experiments with low and high specific surface area fumed silica at various addition levels confirms that both specific surface area and dosage of fumed silica are key parameters for tuning ceramic transparency and haze. Through multiple mechanisms, including nano-filling, optimization of sintering kinetics, and surface chemical regulation, fumed silica enhances transmittance while maintaining stable haze, offering robust theoretical support for the scalable production of high-performance transparent ceramics.

In the future, deeper integration of fumed silica surface modification technologies with advanced ceramic forming processes is expected to drive breakthrough applications of transparent ceramics in extreme-environment optical devices, biomedical materials, and other cutting-edge fields, propelling China’s new materials industry toward the high end of the global value chain.